Essential Wood Terminology: A Craftsman's Guide to Wood Language

Len Wasik

A detailed overview of various wood types used in furniture making, highlighting their unique properties and applications.

Understanding woodworking terminology is crucial whether you're a seasoned craftsperson or just beginning to explore the world of custom furniture. At Refined Rustic Furniture, we believe knowledge empowers better decisions about your custom pieces. Here's our comprehensive guide to common wood terms, organized by category.

Wood Characteristics & Structure

Heartwood: The inner core of a tree, typically darker and denser than the outer layers. This is the non-active, dormant part of the tree.

Sapwood: The living, outer portion of the tree, usually much lighter in color than heartwood.

Grain: The direction, size, arrangement, and appearance of wood fibers. Can be:

Cross Grain: Running perpendicular to the main grain

Interlocked Grain: Multiple longitudinal directions in alternating layers

Raised Grain: Roughened condition when hard late wood rises above soft early wood

Figure: The natural pattern produced by growth rings, rays, knots, and grain deviations.

Cutting & Processing Terms

Board Foot (BF): Standard measurement equal to 144 cubic inches of wood. Calculate by: (length × width × thickness in inches) ÷ 144

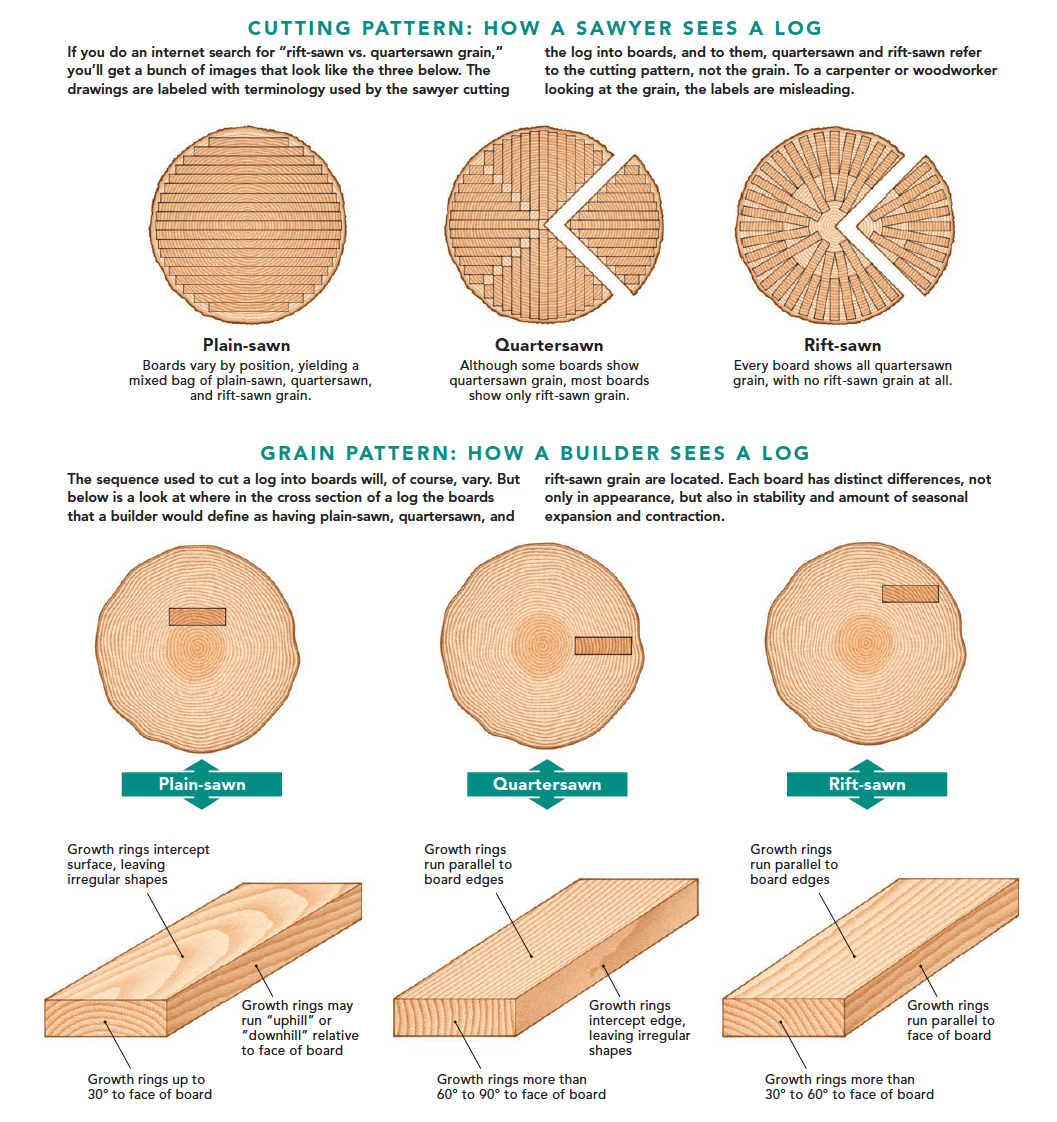

Plain-Sawn: Lumber cut with annular growth rings parallel to the board's face

Quarter-Sawn: Wood cut so growth rings run parallel along the entire board, offering:

Better dimensional stability

Less seasonal movement

Reduced twisting and cupping

Enhanced rot resistance

Rip Cut: A cut running through the board's length parallel to the grain

Wood Conditions & Drying

Air Dried: Wood naturally dried without kiln processing. Moisture content varies by location.

Kiln Dried: Oven-dried wood with controlled moisture content:

10-12% for outdoor use

6-8% for indoor use

Green: Freshly sawn lumber

Decorative Features & Special Cuts

Book Matched: Adjacent pieces cut and opened like a book, creating mirror-image patterns

Burl: Unique knotty growth with swirled, twisted grain patterns

Cathedral: Grain pattern showing stacked, inverted "V" shapes

Live Edge/Natural Edge: Incorporating the tree's natural edge into furniture design

Crotch Wood: Section where branches divide, featuring complex grain patterns

Common Features & Defects

Checks: Small slits parallel to wood grain, typically from drying

Knots: Cross-sections of tree branches within the wood

Knot Holes: Openings left when knots fall out

Specialized Pieces

Bolt: Short log, typically 2'-8' in length

Cookie: Full round cross-cut slice of a tree

Flitch: Large wood piece cut from a log

Slab: Broad, flat, thick piece of wood

Veneer: Thin wood sheet (usually ¼ inch or less) used in fine woodworking

Working With Wood

Finger Joint: Interlocking end joints held together with adhesive

Joint: Common edge between adjacent materials

S4S: Surfaced four sides (edged and planed)

Wane: Edge showing remaining bark or trunk surface

Understanding these terms helps you make informed decisions about your custom furniture pieces. Have questions about specific wood terminology? Our craftsmen are always happy to explain the technical aspects of our work.

Read More…